A threaded insert is a versatile component widely used across industries, originally designed as a fastening solution. Traditional threaded inserts often take the form of nuts embedded into materials for securing bolts. However, our threaded insert goes beyond the conventional, functioning as both a connector and a fastener, tailored for diverse applications. Thanks to its shape and functionality, our threaded insert is also referred to as a tube connector, tube adaptor, or star nut.

Our Threaded Insert: Redefining Connections

Our threaded insert stands out by providing reliable connections across various scenarios:

- Pipe-to-pipe connections.

- Pipe-to-surface connections.

- Pipe-to-leveler connections (such as levelers or casters).

The core design centers around the star nut, with specific adaptations for each use case:

1.Pipe-to-pipe connection:

- The star nut with a bolt or as the primary connector ensures secure fastening between two pipes.

- Aesthetic enhancements are possible by incorporating metal washers.

2.Pipe-to-surface connection:

- A combination of a regular nut and a star nut serves as the connecting mechanism, providing stability for attaching pipes to flat surfaces.

3.Pipe-to-leveler connection:

- A star nut with a tray connects to the pipe, supporting the installation of casters or levelers at the base.

Compatibility and Versatility

Our threaded insert is designed to fit round, square, and rectangular pipes, ensuring compatibility with most furniture tubing on the market. Connection methods include:

- Threaded connection: Traditional bolted systems.

- Pintle connection: Particularly useful in office chairs for pipe-to-caster interfaces.

Installation Methods:

- Hammering: A simple method for embedding the insert into the pipe.

- Pneumatic tools: For quicker and more efficient installation.

This versatility makes our inserts ideal for most furniture manufacturing applications, supporting the dimensions of commonly used furniture pipes.

Engineering Excellence

Our threaded insert offers a range of features engineered for durability and performance:

Spring Washer Design:

- Up to 4 layers of spring washers, providing a maximum pull-out force of 300 kg—virtually impossible to remove by hand.

- Double-layer spring washers, commonly used for caster connections, come in high and low-profile versions, catering to different design needs.

2.BIFMA-certified Patented Products:

- A specialized plastic version of our insert combines high-quality materials with spring washers, ensuring compliance with industry standards.

3.Materials and Surface Treatments:

- Spring washer: Made from high manganese steel with a blackened surface for durability.

- Trays, bolts, and other components: Customizable finishes, including zinc plating, nickel plating, chrome plating, or blackening, to provide protection against rust and corrosion.

Advantages of Our Threaded Insert

- Facilitates Modular Furniture Design:

- Simplified installation reduces manufacturing time, enabling modular furniture construction.

- Compact designs minimize shipping volume, significantly lowering transportation costs.

- Improves Manufacturing Efficiency:

- Eliminates the need for traditional welding, reducing safety risks, labor costs, and time spent.

- Enhances the productivity of furniture manufacturers.

- DIY-Friendly:

- Easy to install and replace, making it user-friendly for end consumers.

- Applications Beyond Furniture:

- Widely used in bicycle handlebar and frame connections, offering an additional revenue stream for distributors and retailers.

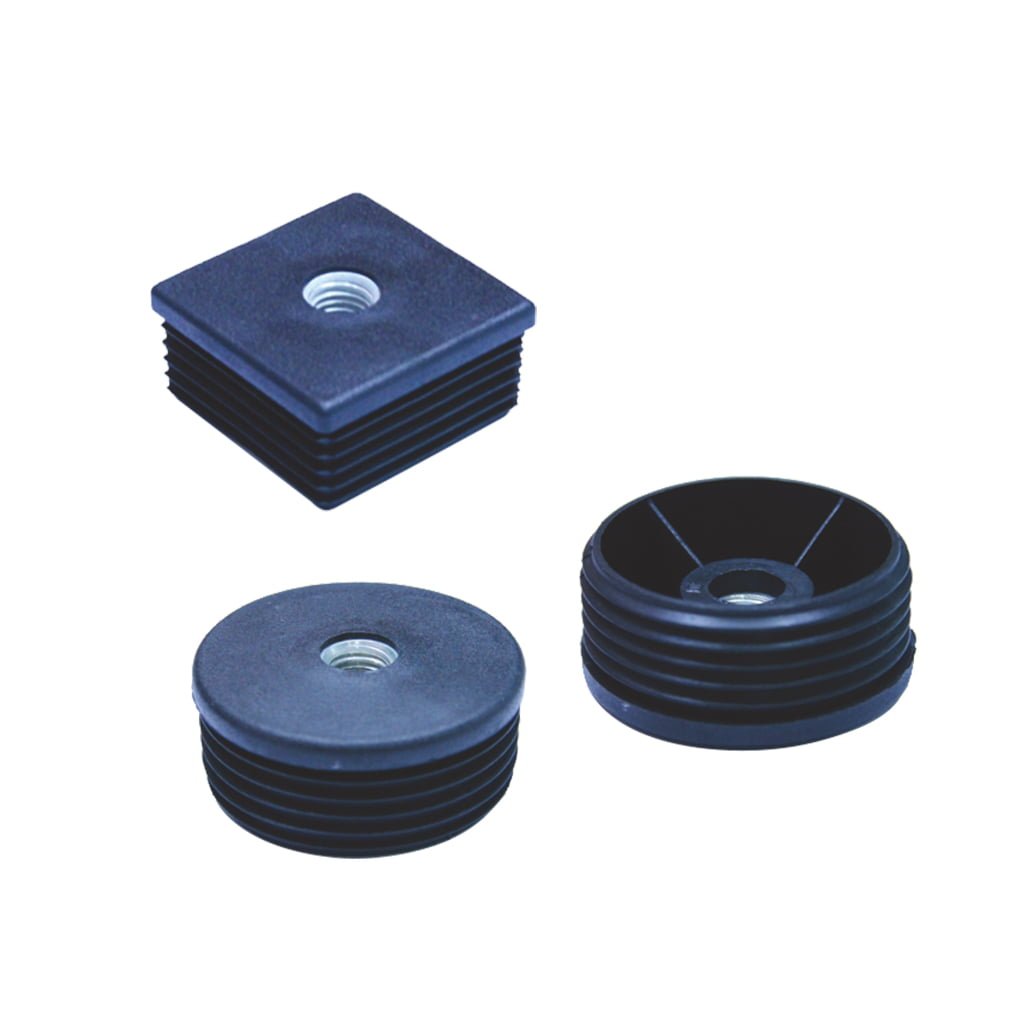

Plastic Threaded Inserts

In addition to metal options, we also offer plastic threaded inserts, ideal for environments requiring lightweight or corrosion-resistant solutions. These are particularly suited for outdoor furniture, moist areas, or chemical-prone environments.

Choosing the Right Threaded Insert

When selecting a threaded insert, consider the following:

- Pipe dimensions:

- Outer diameter, inner diameter, and wall thickness are critical measurements to ensure proper fit.

- Use Case:

- Determine the application scenario, such as indoor furniture, outdoor furniture, or office chairs. For standard furniture, a single-layer spring washer is sufficient.

- Environmental Conditions:

- For moist, outdoor, or chemical environments, ensure appropriate surface treatments (e.g., galvanized or blackened finishes) to prevent corrosion.

Conclusion

Our threaded insert is more than just a fastener—it’s a transformative solution for modular furniture design and beyond. With options for metal and plastic, unparalleled adaptability, and robust engineering, it supports diverse applications in furniture manufacturing, retail, and even bicycles. Whether for manufacturers or end-users, our threaded insert delivers a perfect blend of efficiency, durability, and ease of use.